Showing 37–48 of 120 results

-

Zirkonzahn 5-TEC Dental Milling unit M5 White + Zirkonzahn S600 Scanner

$8,900Features :

-5+1 axes simultaneous milling and orbit technology

-2, 3, 4 or 5 milling spindles

-Multitasking

-Milling Spindle Soft Automatic M5 with automatic tool changer

-Milling Spindle Hard Automatic M5 with automatic tool changer

-Wet processing function Wet Grinding/Wet Milling M5

-Speed-Upgrade Metal M5

-Airbrush and laser writing

-Support for precast titanium abutment blanks Raw-Abutment®

-Support for precast bridge blanks Bridge-Rod

-Equipped with blocking airTechnical specifications

Weight : 210 kg

Width : 123.2 cm

Height : 69 cm

Depth : 53 cm (plus connection for suction unit)

Glass lining : Hardened Sicurit glass UNI ISO 12150

Processing axes : 5+1

Power capacity : 600 W

Operating voltage : 230 V (115 V)

Power input : 2.6 A (5.5 A)

Chuck : Ø 3 mm

Spindle speed : max. 50,000 R.p.m.

Spindle motor : 100 W

Block diameter : Ø 95 mmIncluded package :

– 1x Zirkonzhan Milling unit M5 White

– 1x Zirkonzhan Scanner S600 ARTI White

– Kit Wet Grinding/Wet Milling M5

– New Milling Spindle Hard Automatic M5

– PC and screen

– CAM software

– Workbench Milling Unit M5 Heavy and M3 -

3shape D2000 3D Dental Scanner

$6,900Product Description

Complete case in one scan – no need to scan models, dies and bite separately

Optimized multi-line technology & processing for fast case throughput

Simultaneous scanning of Upper and Lower model

RealColor Technology – capturing all textures and colors on the model for lifelike design

Technical Specifications

* Resolution : 4 x 5 MP cameras, Blue LED Multi-line

* Accuracy: 5 µm (ISO) / 8 µm (Implant bar)

* Die scan time: 15 sec

* Full arch scan time: 25 sec

* Color texture scanning

* No need for separate die scan

* All-in-one scanning: room for 2 modelsIncludes

* 1 x Scanner calibration object,

* 3 x Scanning interface plate,

* 1 x Blu-Tack scan clay,

* 1 x Dongle USB key

* 1 x Multi-Die Fixture ,

* 1 x Scan Height Adapter ,

* 1 x Occlusion Transfer Calibration Object* 1 Years Manufacture 3Shape Warranty and Extend 1-year.Totally 2-Years warranty.

-

3Shape D1000 3D Dental Scanner System

$6,800Product Description

Ultra-high productivity

* 4 x 5 MP cameras. Blue LED Multi-line.

* With Multi-Scanning and Color Texture Scanning.

* Expanded interior space for mounted models etc.

* No need for separate to scan.Desktop PC

* High performance PC (model subject to change)

* Operating system and CAD software pre-installed

* Mouse and keyboard included (monitor NOT included)Operating System & Recovery

* Windows 8 Pro, 64-bit, English (Support for 35 languages)

* Windows 8 Pro Recovery Partition on hard driveDental System™ Premium CAD Software Package

* Dental Designer; see page 18 (CAD software, 1 seat)

* Dental Manager (5 seats)

* Dental Manager Inbox (Order reception and filtering software, 10 connections)

* TRIOS® Inbox (TRIOS® order reception and filtering software)FREE Trial Software Modules

* Abutment Designer / Implant Bars and Bridge Design (Limited saves: 20/5)

* Removable Partial Design (Limited saves: 15)

* Model Builder™ – TRIOS® (Limited saves: 20)Help System

* Integrated online user manual (12 languages)

Includes

* 1 x Scanner calibration object

* 3 x Scanning interface plate

* 1 x Blu-Tack® scan clay

* 1 x Dongle USB key

* 1 x Multi-Die Fixture

* 1 x Scan Height Adapter

* 1 x Occlusion Transfer Calibration ObjectOptional

* Add-on Modules and Module Upgrades

* CAD Points

* Additional Seats

* Extended Warranty

* Various add-on modules and Module Upgrades are available

* Pay-Per-Design option for selected add-on modules. Purchase in webshop

* Additional seats can be purchased

* Extend the 1-year limited warranty on 3Shape hardware by 1 or 2 additional years

-

3Shape D900 Series Dental Scanner

$6,500New ! 3Shape D900 LED Dental Scanner in Color

3Shape D900 scanner very high scan-speeds, unique color scanning capabilities, enhanced details and high accuracy. Four high-res 5MP cameras and new blue LED technology provide extraordinary speed and highly accurate color scanning. Perfect for large high volume, productive-oriented labs.

RealColorTM Technology captures all textures and colors

Texture scanning captures 2D images of the model surface and precisely overlays these on the 3D model, enhancing visualization of surface details and allowing technicians to include had drawn design guidance markings in the digital design. RealColorTM Technology on the D900 allows technicians to capture colored markings, indicating different design details.Implant bridge and bar accuracy

high-end scanners to produce implant bars and bridges of an exceptional quality that few other can deliver. 5.0 Mega-pixel cameras, in combination with high quality scan abutments, enable accurate 3D capture of both implant positions and orientations ensuring excellent passive fit.High productivity with Multi-Die scanning

Multi-Die scanning provides labs with efficient batch and multi-case processing. Dies for one or more cases are fixed to the Multi-Die plate, and scanning is automatic, freeing the technician to work with other tasks. Next generation multi-die technology on the D900 optimizes speed and performance without compromising accuracy.D900 Specification :

Cameras : 4 cameras

Light technology : Blue LED

Accuracy : 15 microns

Gypsum model scanning : Yes

Impression scanning : Yes (add on)

Multi-die scanning : Yes (new technology)

Texture scanning : Color Texture

Scan time – single die 15 Sec (19 sec)

Scan time – 3 unit bridge 65 Sec (85 sec)

CAD Software package : Included -

3Shape D810 Dental Scanner

$5,000Combining accuracy and speed with Multi-Die scanning capabilities

The 3Shape D810 Dental Scanner takes labs to whole new productivity

levels with high speed scanning, and ultra-efficient batch and

multi-case processing capabilities.

With its new and unique Texture Scanning feature plus 5.0 megapixel

cameras, 3Shape’s D810 scanners wield the market’s most advanced 3D

scanning technologies. 3D scanning in connection with designing

implant bridges and bars requires very high accuracy. 3Shape’s D800

series scanners are among the few that can deliver reilable data for

these indications.

Capture complete textures and pencil markings

Implant bridge and bar accuracy

Market’s most extensive suite of scan indications

High productivity with Multi-Die scanningD810

Highly Accurate Scanning

Scan time Die: 25 sec (30 sec)

Resolution 2 cameras, 5.0 Mega Pixels

Accuracy Ultra High accuracy: < 15 Microns

Texture Scanning technology High detail detection and capture of

hand-drawn markings on model

Multi-Die Scanning Scan batches for single or multi-case processing -

3shape D800 3D Dental Scanner

$5,800Texture Scanning, 5 megapixels & Multi Die technology

The 3Shape D810 Dental Scanner takes labs to whole new productivity

levels with high speed scanning, and ultra-efficient batch and

multi-case processing capabilities. With its new and unique Texture

Scanning feature plus 5.0 megapixel cameras, 3Shape’s D810 scanners

wield the market’s most advanced 3D scanning technologies.Implant bridge and bar accuracy

3D scanning in connection with designing implant bridges and bars

requires very high accuracy. 3Shape’s D800 series scanners are among

the few that can deliver reilable data for these indications. The 5.0

megapixel cameras enable perfect 3D data capture of both implant

positions and implant orientations to ensure a perfect tension-free

fit of the produced bridge or bar when seated.Capture complete textures and pencil markings

Utilizing its 5.0 megapixel cameras, the high-end D800 scanners

support unique Texture Scanning capabilities. Texture Scanning

provides enhanced visualization of surface details and allows

technicians to capture hand-drawn design guidance markings made

directly on the model and transfer these into the digital design.Scanning the market’s most extensive range of dental indications

Antagonist model, Pre-preparation

Impression scanning (Add-on Module)

Model builder for impression and intraoral scans (Add-on Module)

Single coping

Bridge framework

Anatomical copings and framework

Full anatomical crown

Full anatomical bridge

Single wax up/ Wax up bridge

Inlay / Onlay / Inlay bridge

Veneers

Over-press crowns and bridges

Post & core

Telescope

Customized abutments (Add-on Module)

Implant bars and bridges

Removable partial design (Add-on Module)

Orthodontics module (Add-on Module)Scan Indication Fixtures

3Shape has designed special accessories for your scanners to ensure

fast, problem-free, and precise scans with high quality digital data

for even the most complex indication types.

The impression fixture – Enables automatic alignment of upper and

lower when scanning triple-tray impressions. The impression is fixed

in a permenant position in the flippable holder. The scanner and

software can recreate the precise upper and lower relationship in the

digital model.

The wax-up fixture – enables scanning of wax-ups and bits from all

angles and sides. The wax-up is suspended in wires that will be

invisible in the scan result.

Two-cast fixture – enables users to firmly set 2 models, preparation

and antagonist, in occlusion so they do not move during scanning. The

Two-cast fixture functions like a clamp making it easy to set while

holding the models in occlusion.

D800

Highly Accurate Scanning

Scan time Die: 25 sec (30 sec)

Resolution 2 cameras, 5.0 Mega Pixels

Accuracy Ultra High accuracy: < 15 Microns

Texture Scanning technology High detail detection and capture of

hand-drawn markings on model

Scan indications Market’s most extensive range. -

3shape D700 3D Dental Scanner

$3,7503Shape’s D700 series scanners are for medium to large labs where

productivity and flexibility are the key criteria. The Scanner comes

with “Dental System Premium”

3Shape’s unique 2-camera and 3-axis motion system

2 cameras with reduced angle enable impressions,deep inlays, and full

undercuts to be scanned effectively.

The 3-axis motion system allows the dental object to be tilted,

rotated, and translated, facilitating scanning from any viewpoint and

enabling scanning of more than 350 degrees of a sphere.

Scan parameters are automatically adjusted to the object’s material

for accurate color capture.

Scan time (Final 3D model) Single die: 25 sec (30 sec), Full model: 60

sec (75 sec)

Resolution 2 cameras, 1.3 Mega Pixels

Accuracy High accuracy: < 20 Microns

Material color Material color independent

Scan indications Market’s most extensive range.

Dimensions (W x H x D) 34 x 29 x 33cm (14″ x 11″ x 13″)Scanning the market’s most extensive range of dental indications

Antagonist model, Pre-preparationImpression scanning (Add-on

Module)Model builder for impression and intraoral scans (Add-on

Module)Single copingBridge frameworkAnatomical copings and

frameworkFull anatomical crownFull anatomical bridgeSingle wax up/ Wax

up bridgeInlay / Onlay / Inlay bridgeVeneersOver-press crowns and

bridgesPost & coreTelescopeCustomized abutments (Add-on Module)Implant

bars and bridgesRemovable partial design (Add-on Module)Orthodontics

module (Add-on Module -

3Shape D500 Dental Scanner

$3,1503Shape D500 Dental Lab CAD Scanner with Computer

Decriptions:

– Optimized Scanning: Quick, high resolution scanning of gypsum and impression models. Single die: 50 sec (55 sec) Full model: 100 se (115 sec)

– High Resolution: 2 cameras (3 axis movements), 1.3 Mega Pixels

Extremely Accurate: High accuracy: < 20 Microns

Dental System Standard: Covers all basic dental indications, including

copings, bridges, full contour crown and bridges, wax ups and

inlays/onlays.3Shape’s user-acclaimed 3D scanning for any lab

The D500 is designed to provide powerful 3D scanning for any

laboratory size and budget. With support for impression scanning

capabilities, the D500 represents one of the market’s most attractive

entry-level investments.Your cost-efficient CAD/CAM soution

The D500 compact dental scanners are built on 3Shape’s leading

scanning technologies and come with the range of dental indications

provided in Dental SystemTM Standard.Ensure your future with this upgradable scanner

The D500 scanner is upgradable to Dental System Premium for extending

the range of available indications and widening your business scope.

2 Cameras and 3-Axis Scanning

The D500 is built with 2 cameras with reduced angles, which is

required to effectively scan impressions and deep inlays. The scanner

employs a unique 2 cameras and 3-axis motion system, which results in

unrivaled accuracy in object geometry acquisition. The 2 cameras with

reduced angle enables the D500 to effectively scan complicated

geometries; areas where a single camera often will be blinded by the

cavity. Two cameras also improve general coverage and accuracy.The impression scan can be applied directly in 3Shape DentalDesigner

like any gypsum model scan and sets new standards for system

applicability. In combination with DentalDesigner™ the new D500

scanner brings unprecedented scan-to completed design time to the

market for digital dentistry. attractive opportunities in terms of

manufacturing cost, model creation speed and quality.The created virtual model – saved as STL – is sent to digital model

making machines, which are currently evolving rapidly, driven by

impression and intra oral scanners. Use either a 3D printer or a mill

to produce casting patterns, or a milling machine with zirconia blocks

to produce finished parts for direct implant. A physical model can

also be used to show the impression to the patient or dentist – to

initiate client and lab communication – especially when scanning in

the dentist’s office.. -

3shape D710 3D Dental Scanner

$4,5003Shape’s D710 series scanners are for medium to large labs where

productivity and flexibility are the key criteria. The Scanner comes

with “Dental System Premium”.

High speed scanning

The D710 is optimized for scanning both impression and gypsum models

and enables high throughput for both standard and advanced

indications.

Its that easy

These advanced dental scanners are so easy to use that extra staff

training is hardly required. Object fixation is quick, and a single

click in the software starts the scan.Scanning the market’s most extensive range of dental indications

Antagonist model, Pre-preparation

Impression scanning (Add-on Module)

Model builder for impression and intraoral scans (Add-on Module)

Single coping

Bridge framework

Anatomical copings and framework

Full anatomical crown

Full anatomical bridge

Single wax up/ Wax up bridge

Inlay / Onlay / Inlay bridge

Veneers

Over-press crowns and bridges

Post & core

Telescope

Customized abutments (Add-on Module)

Implant bars and bridges

Removable partial design (Add-on Module)

Orthodontics module (Add-on Module)

Multi-Die scanningScan Indication Fixtures

3Shape has designed special accessories for your scanners to ensure

fast, problem-free, and precise scans with high quality digital data

for even the most complex indication types.

The impression fixture – Enables automatic alignment of upper and

lower when scanning triple-tray impressions. The impression is fixed

in a permenant position in the flippable holder. The scanner and

software can recreate the precise upper and lower relationship in the

digital model.

The wax-up fixture – enables scanning of wax-ups and bits from all

angles and sides. The wax-up is suspended in wires that will be

invisible in the scan result.

Two-cast fixture – enables users to firmly set 2 models, preparation

and antagonist, in occlusion so they do not move during scanning. The

Two-cast fixture functions like a clamp making it easy to set while

holding the models in occlusion.Jumpstart the digital design process

Impression scanning, including intra oral, is storming ahead in

today’s dental arena and represents a technology that must be

considered when investing in a new scanner. Gypsym-only scanners may

not represent the most future-secure choice. 3Shape’s 3D scanners can

scan both gypsym models and impressions with fast adaptive impression

scanning, at times below 2 minutes.Impression scanning reduces turnaround time

Direct scanning of silicone and alginate impressions enables labs to

start CAD design immediately and manufacture model, coping and crown

in parallel.Enhancing accuracy with direct scanning of impressions

Impression scanning eliminates inaccuracies that can occur when

producing a plaster model from a physical impression.Impression scan to virtual model

Turn the impression scan to a virtual model by applying tools for

articulation, trimming of scan, base creation, sectioning of

preparations (preserving gingiva), and articulator interface.3Shape – leading impression scanning technologies

3Shape’s patented adaptive scanning technology, combined with the

scanner’s 3-axis motion and 2 cameras with reduced angle, facilitate

the unique impression scanning capability. Adaptive scanning

intelligently detects incomplete areas and automatically builds

adaptive scan sequences for capturing full object geometry -

Roland monoFab SRM-20 Desktop Milling Machine

$2,980As a small milling machine, the SRM-20 offers compact size and powerful functionality at an affordable price. Production of realistic parts and prototypes is made simple and convenient with a device that fits into any office, home, or classroom environment. For users looking for advanced milling capabilities without the need for expert operating skills, the SRM-20 is the easiest and most precise CNC mill in its class.

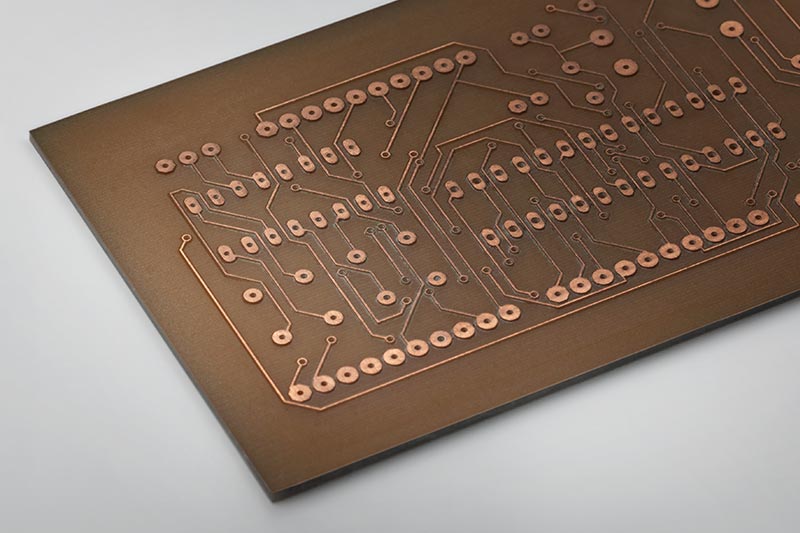

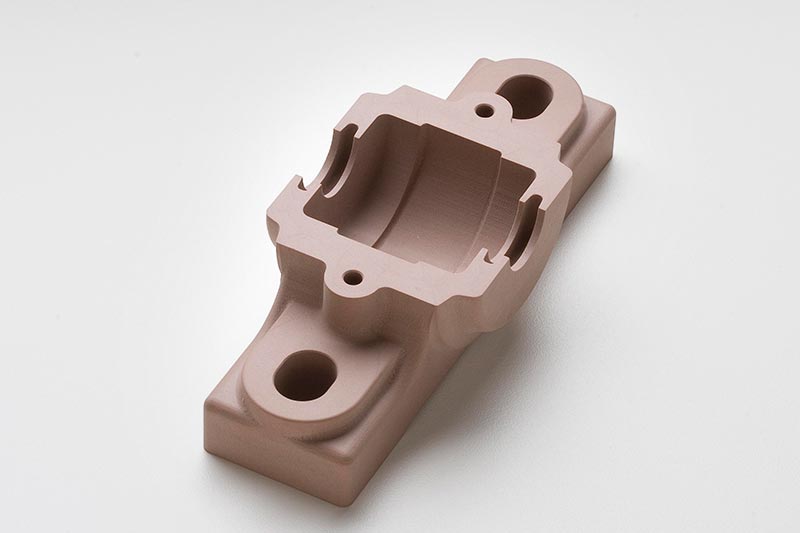

Create Realistic Prototypes

A wide range of materials, including modeling wax, chemical wood, foam, acrylic, poly acetate, ABS and PC board can be precision milled using the SRM-20 small milling machine, allowing you to create realistic 3D prototypes that are virtually identical to production parts.

Precision and Productivity

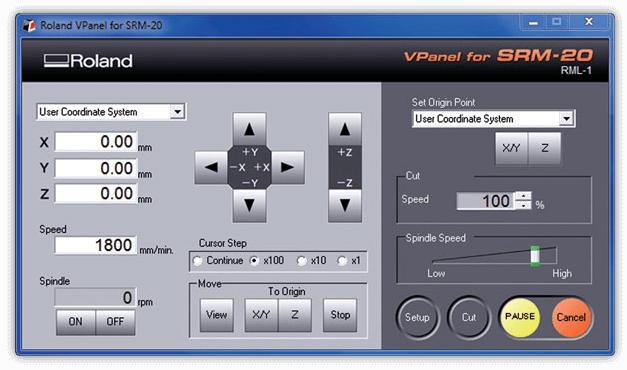

Engineered for optimum efficiency and productivity, the SRM-20 is a next-generation desktop mill that boasts a micro-step motor drive system for clean and precise contours and a phenomenal feed rate that’s two times faster than previous generations.Multi-axis milling is as easy as X, Y and Z

The SRM-20 was designed with a number of technological advancements that include a touch-button VPanel controller to regulate feed rate, spindle speed and milling on a complete X, Y, Z axes, and a new independent collet system that allows for faster setting of the Z-axis base point and quick tool changes.

Distinguishing Features

Subtractive Prototyping of Complex Snap Fits

Maximum axes operation: 8″(X) x 6″(Y) x 2.38(Z)

Bundled Software Suite, including SRP Player

Powerful Spindle Motor

Independent Collet System

G-Code Compatible -

Roland DWX-52DC Dental Milling Machine

$9,800Highly Productive Unattended Milling

Power it on, let it go, and automatically mill numerous dental restoration jobs with complete unattended confidence.

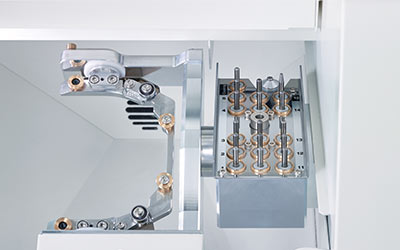

Increase productivity overnight and during the weekends with a dental mill that continues working, even when your office is closed.Load up-to six different 98.5mm disks and mill numerous restoration jobs in succession.An Automatic Disk Changer (ADC) enables continuous milling of multiple jobs in zirconia, WAX, PMMA, composite resin, PEEK, gypsum, pre-sintered soft metal and fiber reinforced resin. It also optimizes user workflow by milling different shades of zirconia at once.Automatic Tool Changer (ATC) features up-to 15 tools that swap-out automatically.DWX-52DC Dental Milling Machine Features

Automatic Disc Changer

(ADC)Load the six O-Clamp material adapters with different shades of zirconia or any combination of material discs to suit your needs. Assign them with milling jobs and let the automatic disc changer do the rest.

Material adapters can be individually labeled and barcoded to enable VPanel recognition of each disc position. Organize job assignment via your CAM software for non-stop production..

Automatic Tool Changer

(ATC)Load the 15-station ATC with a variety of diamond coated, carbide and Roland hybrid tools to continuously mill jobs in different materials and multiple shades of zirconia without stopping production.

Intelligent Tool Changer

Part of the simplified VPanel operation, an ITC function automatically swaps out tools that have reached their user-defined lifespan with a designated “partner tool” without needing to pause production.

-

ROLAND DWX-50 5-AXIS DENTAL MILLING MACHINE

$6,900The DWX-50 5-axis dental milling machine delivers the advanced features that dental labs need at an attractive price point, all backed by Roland’s proven reliability and legendary support.

Designed to streamline the production process, the DWX-50 features 5-axis simultaneous machining capability, a 5-station automatic tool changer with tool length sensor, and a diagnostic notification system that allows for minimal operator involvement. An integrated air blower system and an advanced dust collection system makes this one of the top Zirconia milling machines on the market. The built-in dust collection tray can be easily connected to any lab vacuum system, keeping the cutting area clean and free of debris.

The DWX-50 is built on open technology, allowing for easy integration with CAD software and scanners. Additionally, the DWX-50 offers multicast capability, making it possible to connect up to four machines to one computer, allowing you to grow your business by adding additional production capability at a fraction of the cost.

- Zirconia Milling Machine

- Five-station automatic tool changer with tool length sensor

- Diagnostic notification system alerts user of machine status

- 5 axis dental milling machine capable of 5-axis simultaneous machining to achieve complex cuts

- Mills wax, zirconia, PMMA and Lava™ Ultimate with precision

- Diamond-Coated Tools Now Available

- Approved for 3M ESPE Lava™ Ultimate Restorative*

- Built-in dust collection tray for easy connection to any vacuum system

- Air blower system to aid difficult to machine materials

- Ideal for creation of copings, crowns, bridges and abutments

- Innovative clamping system securely holds a wide variety of materials

- Simplified Virtual Panel enables easy operation

- G-code compatible

- Compact design is well suited for small office spaces or laboratories

- Ability to connect four DWX-50 machines to one computer

- Compatible with industry standard software

- Open architecture design for easy integration into a complete milling solution

Advanced Features Make for Error Proof Production

The DWX-50 is Roland’s most advanced dental milling machine to date. Developed expressly for the production of dental prosthetics, the easy to use DWX-50 features a 5-axis simultaneous machining capability and a 5-station automatic tool changer with tool length sensor that lend to the convenience factor by fully automating the production process.

5-Axis Simultaneous Machining

The DWX-50 features 5-axis simultaneous machining, milling on X,Y, Z axes and rotating the blocks and discs of material 360 degrees in both clockwise and counterclockwise movements. This also allows for materials to be tilted forward and backward 20 degrees to support complex cuts.Five station Automatic Tool Changer

The five station Automatic Tool Changer with a tool length sensor enables the user to run multiple tools for one job, or to run an entire disc unattended. Instead of inspecting finished pieces to determine if everything was milled correctly, the integrated tool diagnostics feature will notify users if a tool was broken prior to completion, resulting in reduced waste. Using the tool length sensor, the automatic tool changer will also verify that a tool was properly placed back in the magazine, preventing mechanical failures.

Clean Cutting Area Lends to Precision

Equipped with an integrated air blower system that aids with difficult-to-machine materials, such as zirconia and PMMA, the DWX-50 also features a built-in dust collection tray that can be easily connected to any lab vacuum system, keeping the cutting area clean and free of debris.Virtual Machine Panel

The DWX-50 features Roland’s legendary Virtual Machine Panel or VPanel for short. Serving as the main operation panel for the DWX-50, the VPanel allows the user to automatically start the milling process or manually reposition the tools, clamp or quickly set origin points, all from their computer desktop. The VPanel is also equipped with an easily accessible hour meter to keep track of overall machine time for maintenance purposes.Open Design for Easy Integration

Built on open technology, the DWX-50 is G-Code compatible and supports a wide range of software and tools, allowing for easy integration with any commercially available dental prosthetic production solution. It can take industry standard materials as disks or blocks.

Roland DWX series dental mills are capable of producing a variety of dental restorations from a wide range of materials with high precision. The DWX-50 dental CAD/CAM milling machine features 5-axis simultaneous milling and a 5-station automatic tool changer for unattended milling of standard 98 mm discs and blocks including:

Materials

- Wax for lost-wax castings of gold or leucite

- Porcelain for PFM (porcelain-fused-to-metals such as alumina)

- Zirconia

- PMMA

- e.max PRESS ceramic

- VITA ENAMIC hybrid ceramic

- 3M ESPE Ultimate CAD/CAM Restorative nano ceramic resin

Crowns

For permanent restorations that completely cover a tooth or dental implant, strength, margins and aesthetics are key considerations. With 5-axis simultaneous milling and 5-station automatic tool changer, the DWX-50 can easily mill 25 to 30 crowns overnight from a single disc of zirconia, wax or PMMA. You can also mill precision crowns from newer ceramic materials that don’t require sintering, including standard blocks of VITA ENAMIC hybrid ceramic or 3M ESPE Ultimate CAD/CAM Restorative nano ceramic resin.

Copings

Coping refers to that part of a crown that covers the prepared tooth and can be easily milled by the DWX-50 dental CAD/CAM milling machine from wax or plastic for casting, or from a thin ceramic material to which porcelain is applied.

Bridge

The DWX-50 can mill bridges of any size from wax, PMMA or zirconia, VITA ENAMIC or 3M ESPE Ultimate CAD/CAM Restorative.

Bars

A bar connects two implant abutments and requires the ability to produce a flat surface. With its 5-station automatic tool changer, the DWX-50 mills bars from zirconia for outstanding strength and precision.

Abutments

An abutment is a tooth that supports a bridge or partial denture. The DWX-50 is capable of milling a variety of abutments including hybrid, screw, glue-based, etc., from a variety of restorative materials.

Inlays and Onlays

Indirect inlays (intracoronal fillings) and Onlays (cusp fillings) can be milled from wax for casting metal, or from porcelain, zirconia or composite materials. With its 5-station automatic tool changer, the DWX-50 dental CAD/CAM milling machine provides the ability to produce required sharp angles from small tools.

Pontics

A Pontic is that part of a fixed bridge that is suspended between abutments and replaces a missing tooth. The 5-axis simultaneous milling and 5-station tool changer allows the DWX-50 to perform the precision undercuts required.

Temporaries

The DWX-50 quickly mills gradient temporary crowns and bridges from PMMA that are designed to maintain esthetics, stability and function while a permanent prosthesis is manufactured.

Bite splints

Also known as occlusal splints, bite planes or night guards, bite splints are removable dental appliances precision molded from plastic to fit the upper or lower arches of teeth.